04/01/2021

F-Gas Regulation: When refrigeration equipment operators have to act!

Interview with F-gas experts Rainer Henrici and Christian Teller

The F-Gas Regulation aims to reduce fluorinated greenhouse gas emissions across the EU. We spoke with Rainer Henrici, Senior Project Manager at Infraserv Höchst, and Christian Teller, certified expert in refrigeration and aspiring master builder for refrigeration systems at Infraserv Höchst, about the upcoming challenges facing refrigeration equipment operators.

The current version of F-Gas Regulation No. 517/2014 has been in force throughout the EU since January 1, 2015. What makes the F-Gas Regulation such an explosive topic for refrigeration equipment operators and the chemical industry six years later?

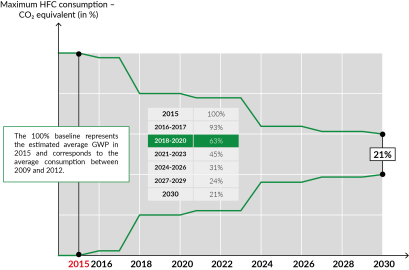

Rainer Henrici: The predecessor F-Gas Regulation primarily addressed factors such as containment, leak detection and recycling. The new version broadens the scope of the bans that will have to be rolled out in stages. For example, refrigerants with a GWP value exceeding 2,500 kg CO₂ have been prohibited in new stationary systems since the beginning of 2020. It is also prohibited to fill existing systems with virgin refrigerants above a certain charge size.