Most common refrigerants to date and their alternatives

After chlorofluorocarbons (CFCs) were partially banned in the 1980s due to their ozone-depleting properties and finally banned completely in the 1990s, Germany decided to only allow non-ozone-depleting refrigerants to be used in new systems.

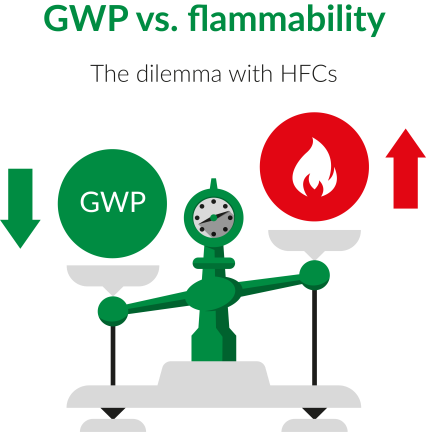

These systems now widely use F-gases (hydrofluorocarbons, or HFCs). However, several of these refrigerants are harmful to the climate due to a strong greenhouse effect. R-410a, which is widely used in stationary air-conditioning systems, has a GWP (global warming potential) of 2,088 and is extremely harmful to the climate; it must not be allowed to leak into the environment under any circumstances.

R-404a, R-507 as well as R-134a, which is mainly used in vehicles, also have high GWP values (3,920, 3,985 and 1,430, respectively). R-134a was banned years ago from air-conditioning systems in new passenger cars since it escapes relatively easily from those types of systems.

The alternatives

R-1234yf is considered a good alternative to R-134a since it has a low GWP of 4 and several properties comparable to R-134a. However, the hydrofluoroolefin (HFO) used in R-1234yf (2,3,3,3-tetrafluoropropene) is mildly flammable (safety group A2L).

There is now a whole range of so-called "low-GWP" refrigerants that contain proportions of HFO such as R-1234yf or R-1234ze. These are mixed with HFCs in certain proportions in order to reduce the GWP value and achieve the desired physical properties. However, refrigerants with a low GWP have a low flammability and are therefore classified in safety group A2L according to DIN EN 378-1.